|

|

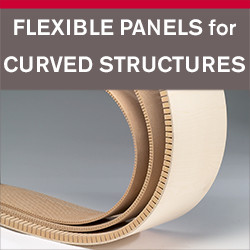

Neatform Fabrication Methods |

|

Neatform and Bending Plywood

|

|

b) Sandwich Method

Description Description

One skin of Neatform either side of

6mm / 1/4” or 9mm / 3/8” bending plywood –

to materials create solid free standing curved shapes.

Example Applications

Used on more structural applications

including: cabinet doors, drawer fronts and decorative walls,

kick boards. This method is particularly good when screw and

hinge holding characteristics are required.

Features

& Benefits

• Heavy- weight applications

• 19mm / 3/4” or 22mm / 7/8” thick (nominal)

+ surfacing

• Screw and hinge holding characteristics

Fabrication

Method

Neatform

and Bending Plywood

Sandwich Method - Directions

1. To create a free standing curved surface

with Neatform Bendy MDF and bending plywood, first

bend the two pieces of Neatform and one piece of

bending plywood to the approximate shape, and roughly

cut to size. Please note that the grooved faces

on the Neatform face inwards.

2. Apply a good even coating

of PVA glue to the mating surfaces of all three

sheets, while noting that it is not necessary for

the Neatform grooves to be filled with glue. A paint

roller is an ideal tool for this job. |

|

3. Sandwich the bending plywood between the two sheets

of glued Neatform and bend to the finished shape.

|

|

4. While the glue is still wet, clamp into shape, applying

moderate pressure, normal to both, faces to ensure

a good bond, and leave to set. Follow the adhesive

manufacturer’s guidance on curing times.

|

|

5. When released, Neatform will retain its shape,

ready for trimming and finishing. |

|

|

|