|

|

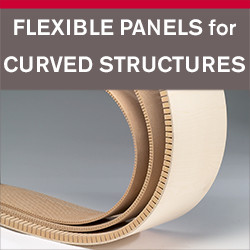

Neatform Fabrication Methods |

|

Neatform and Bending Plywood

|

|

a) Surfacing Method

Description Description

Skin of Neatform used to surface either

6mm / 1/4” or 9mm / 3/8” bending plywood materials

previously attached to a framework.

Example Applications

Improves conventional fabrication

methods by eliminating the problems associated with the poor

surface and inconsistency of bending plywood.

Features

& Benefits

• Fast to fabricate

• 12mm / 1/2” or 15mm / 5/8” thick (nominal)

+ surfacing

• Hides the poor surface, cracks and exclusions in bending

plywood

• Surface ready for finishing

• Screw and hinge holding characteristics

Fabrication

Method

Neatform

and Bending Plywood

Surfacing Method - Directions

1. Fabricate a framework and cover with bending

plywood using conventional techniques.

2. Cut

the Neatform to rough shape and offer up to the

framework to ensure a good fit, positioning the

Neatform grooved face inwards unless making a feature

of the grooved surface. |

|

3. Following the glue manufacturer instructions,

apply a coat of PVA glue or contact cement to

the Neatform and bending plywood and finally position.

If contact cement is used it is essential to ensure

correct positioning is achieved first time because

subsequent adjustment will be impossible.

|

|

4. Hold in position with clamps while PVA glue cures.

Optionally, staples can be used to pin in position,

while the adhesive cures. For further information

on stapling see the section on fabrication tips.

|

|

5. Trim to shape and finish in the normal way. |

|

|

|