|

|

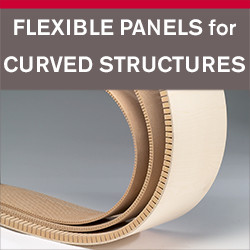

Neatform Fabrication Methods |

|

b) Combination Method

Description Description

Single skin of Neatform attached to

a framework.

Example Applications

This method does not use a framework,

so it can be used to create double-sided structures with visual

impact.

Applications include lightweight screens, display panels,

graphics panels, stage and film sets.

Features

& Benefits

• Free-standing curved shapes

• Light-weight

• Show surfaces on both sides

• 6mm / 1/4” thick (nominal) + surfacing materials

Fabrication

Method

Single

skin

Combination Method - Directions

1. To create a curved surface using the Combination

Method, first bend the piece of Neatform and the

surfacing material to the approximate shape (Neatform

grooved face to surfacing material), and roughly

cut to size.

|

2. Lay both sheets flat (Neatform - grooved face

upwards) and apply a good even coating of PVA

glue to the surface of both sheets, while noting

that it is not necessary for the Neatform grooves

to be filled with glue. A paint roller is an ideal

tool for this job.

Please note –

contact adhesive should not be used with this

method.

3. Place

the sheet of Neatform and the surfacing material

together and bend to the finished shape.

|

4. While the glue is still wet, clamp into shape, applying

moderate pressure, to both faces to ensure a good

bond, and leave to set. Follow the adhesive manufacturer’s

guidance on curing times.

|

5. When released, Neatform and the surfacing material

will retain their shape, ready for trimming and

finishing. |

|

|